To move the two motorized tentacles I developed a proof of concept and on this basis two approaches to realize the movement.

A possible problem could be the weight of the tentacle, but since we have no real scaled tentacle yet, this is just a guess. An actual problem is the movement of the tentacle. If the soul torques to much we won’t get a nice movement, but a twisted mess.

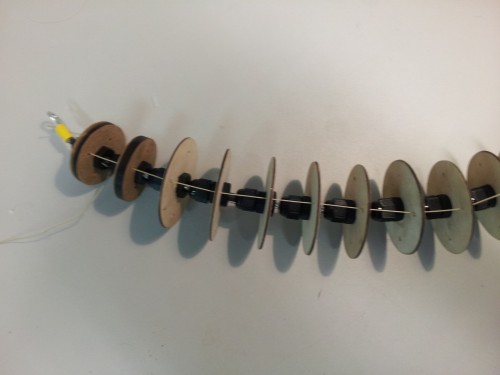

Proof of Concept

Materials:

- flexible tube (6mm)

- flexible tube (10mm)

- some wooden discs

- steel cable

- ground plane

(image will follow)

By pulling the steel cables the tentacle moves in the desired direction. The flexible tube torques to much so the movement is limited to a small percentage, until the tentacle twists. For that reason I was searching for other materials as soul for the tentacle. This prototype is not pretty but functional ;).

Approach 1 – Steel Cable

Materials:

- steel cable 1 m

- some wooden discs

- Aramid fiber thread

- cord strain relief grips.

(video will follow)

For this approach we used a 4 mm steel cable as soul for the octopus. Furthermore we replaced the flexible tube spacers by cord strain relief grips. The wooden discs have different sizes because we just used some leftover wood. But the result was still not perfect, because the steel cables torques to much.

Approach 2 – Bicycle Chain Link

(video will follow)

- aluminium bars 5.5 cm

- some wooden discs

- Aramid fiber thread

- cord strain relief grips.

- bicycle chain links

- some screws and nuts M3

The next idea was to use bicycle chain links to avoid the torsion. Therefore I drilled two holes with 90 degree skew at both ends of a small aluminium pipe. Next I screwed small bicycle chain links to it.

The wooden discs with the cord strain relief grips were attached to the aluminium bar, followed by the next bicycle chain link.

The result looks promising:

But the movement was really disappointing. It was neither smooth curved nor naturally. In retrospect this result is logical. The single chain links have no resistance along the axes so they just move in an acute angle.

Complete bending results in a total mess:

Next I will go back to approach one. Since this approach creates a smooth curve, but torques to much the idea is to use a flexible shaft to reduce the torsion to a minimum.

Approach 1.5 – Flexible Shaft

Since the company GEMO sent us free samples of flexible shafts with a diameter of 4 mm and 5 mm we test them as soul for our tentacles. The results are quite good, so that we will use the flexible shafts and not the steel cable. The main advantage is that the flexible shafts have no twist and can’t torque. So a better controllable movement is possible.