A Framework for a Bicycle Network in Addis Ababa

Master Thesis by Anthea Swart

Study Programme Integrated Urban Development & Design

2019

In this Master Thesis Anthea Swart develops a framework for the creation of a bicycle network in Addis Abeba, the capital of Ethiopia.

This master thesis examines the relatively unexplored situation of cycling as a mode of transportation in developing countries. The benefits of cycling for health, environment and the livability of a city are being highlighted. This topic is explored through the lens of the case study Addis Ababa, the capital of Ethiopia. Due to a rapid population growth and urbanization process the transport situation in the economic center of the country is very tense. The economic upturn is also accompanied by an increase of the motorization rate. However, currently, Ethiopia has still one of the lowest numbers in car-ownership worldwide, this offers the chance to leapfrog the motorization phase and, with the right policy choices, transportation can be made more sustainable.

The main objective of this thesis is to set a framework for the current planning situation of cycling infrastructure in the city of Addis Ababa. The framework includes two dimensions: The political-regulation-communication-dimension and the spatial-design-planningdimension, which both should be considered equally in the planning process. Since the evolution of the bicycle in Addis Ababa, from barely existent towards a proper mode of transportation, will be a long way, it only can be successful with a multilayered and interdisciplinary planning approach.

Regarding the measurements of the first dimension, the ideas and concepts can be summarized from the document analysis and the conducted expert interviews. Therefore the following measures should be highlighted: adapting the curriculum of transport related programs and offering capacity building workshops, adopting legal binding documents, strategies and regulation which ensure enforcement of cycling infrastructure.Furthermore, introducing computer-based analysis, planning and visualization tools, creating tax-incentives for a bicycle industry and finally the very important measure of

communication and awareness-raising actions.

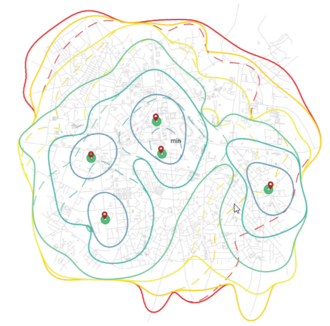

For the second dimension, some spatial parameters are chosen to create different scenarios with the aim to serve as a communication tool between stakeholders and decision-makers. For the specific examination, a research area in the city center of Addis Ababa was picked. From the analysis it emerged, that factors like the location where to start the cycling network and on what type of streets, also the existing street conditions and the terrain need to be considered.

This work hopes to contribute to the current state of research. The results are specific for the situation of this case study, nevertheless, it can be adapted or expanded for other areas and cities.