(Created page with "= das projekt = == das thema == === das unterthema === *liste **unterliste File:supibild1.jpg") |

No edit summary |

||

| Line 1: | Line 1: | ||

= | = LED's Eindrucken = | ||

== 3D Printing around an LED == | |||

== | === The first try === | ||

[[File:Druckkl.jpg|thumb|600px|3D-model and printingprocess]] | |||

To make a LED impression in a trial is not complicated at all. It merely needs a good plan for the process and a little bit of preparation: the LEDs are joined up to each other, the cable soldered, a switching system is thought out and finally a 3D shape is designed to enclose it. | |||

The fabrication process caused some complications. The extruder failed several times because the material got jammed. If noticed on time, the model was not lost, it just showed some flaws; the edges were not refined by another layer. The model was printed with using PLA. Due to the transparency it is a little bit harder to notice if the extruder is still working or not. | |||

For better transparency and faster printing a thin-walled 3D model should be designed, as the translucence is better and also the printing time is considerably shorter. | |||

*1. Trial | |||

**1. The printing process starts with default settings from the program for PLA (with only 180°C printing temperature). | |||

**2. After 45 minutes the plinth base was printed | |||

**3. After 3 hours and 45 minutes congestion of the material. Because of some reason the drive shaft spins, after a while the same problem occurred. | |||

**4. The data cable got partly loose. The carriage is still working but the screw from the material transportation was standing still. | |||

Abort of the printing process | |||

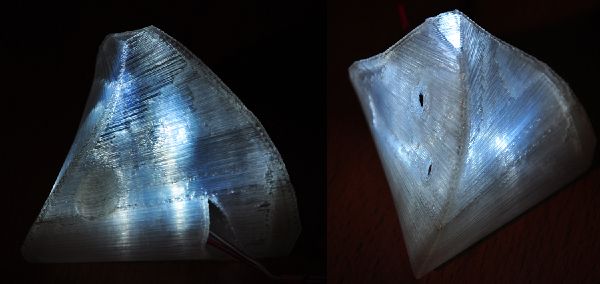

[[File:Ergebniskl.jpg|thumb|600px|Result]] | |||

*2. Trial | |||

**1. New trial with a new model | |||

**2. Presetting for PLA printing temperature: 205°C | |||

**3. Congestion of the material still happens with higher temperature. It is reduced by tightening the screws. | |||

**4. If the fan goes on and off often, this might have to do with the temperature setting, which is exactly on the limit of the cooling and not cooling. | |||

18.Nov.2010 | |||

== www.esters.es == | |||

Revision as of 20:36, 18 November 2010

LED's Eindrucken

3D Printing around an LED

The first try

To make a LED impression in a trial is not complicated at all. It merely needs a good plan for the process and a little bit of preparation: the LEDs are joined up to each other, the cable soldered, a switching system is thought out and finally a 3D shape is designed to enclose it. The fabrication process caused some complications. The extruder failed several times because the material got jammed. If noticed on time, the model was not lost, it just showed some flaws; the edges were not refined by another layer. The model was printed with using PLA. Due to the transparency it is a little bit harder to notice if the extruder is still working or not. For better transparency and faster printing a thin-walled 3D model should be designed, as the translucence is better and also the printing time is considerably shorter.

- 1. Trial

- 1. The printing process starts with default settings from the program for PLA (with only 180°C printing temperature).

- 2. After 45 minutes the plinth base was printed

- 3. After 3 hours and 45 minutes congestion of the material. Because of some reason the drive shaft spins, after a while the same problem occurred.

- 4. The data cable got partly loose. The carriage is still working but the screw from the material transportation was standing still.

Abort of the printing process

- 2. Trial

- 1. New trial with a new model

- 2. Presetting for PLA printing temperature: 205°C

- 3. Congestion of the material still happens with higher temperature. It is reduced by tightening the screws.

- 4. If the fan goes on and off often, this might have to do with the temperature setting, which is exactly on the limit of the cooling and not cooling.

18.Nov.2010