Hacking web cam

In the lab we dissassembled a webcam in order to turn the lens.

The lens must be removed, flipped 180° and glued back in place with a hot glue gun. You need to be very

precise to keep your lens clean and dust free otherwise you will encounter imperfect imaging later on.

We also removed the LEDs with a soldering iron.Mainly, because we will be using different light coming

from the microscope construction, we will be building later.

Miroscopy Stage Construction

With this microscope construction I hope to build a tool that allows me to focus on my analysis without unnecessary material in the way.

I want to be able to twist it in order to use both, bright field and dark field microscopy technics.

Technically, it should be possible to easily change the lights or take off the camera, because there will be no cover material in front of the camera.

3D Model

In Google Sketch Up we created a 3D Version of our microscope construction. Most of my colleges are going to use a 3D Printer.

For that they had to build more complex 3D models. Since I'm going to produce a lazer cut, my model allows different physics.

Because the peaces can interlock and build cross over points I can build it with little material. All peaces have a depth of 1.5 mm.

Stage Construction Cardboard Model

Creating a model in cardboard will help to improve the construction. In fact I did some mistakes in the measurements, I didn't see in the 2D model.

Now I have to figure out the exact mm of every element, because the laser cutter charges every second it runs. I also have to change the side walls, because the model is very fragile.

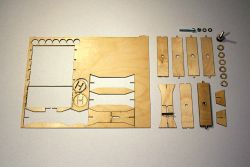

Lazer Cut Components

The illustrator file you have to prepare for the laser cutter looks a little different than this picture below, that has changed colors.

I changed them, because the "ready to go file" has too thin lines. To illustrate the more important issue with this graphic, please look at the overlay of the lines:

The lazer will be running a lot less seconds, because it cuts two sides with one stroke. That is more efficient in money and material.

FSH Assembly

FSH Microscopy Stage Construction

First Microscopy Experiment

Most of the samples I used were very close by. Only for the leave and some soil I went to our garden.

I dug a big hole to find living organisms. I probably found some but the microscope is not zooming enough.

Next week I will try to find some organism that I can capture with this cam.

Idea Scatch from Amel and Nils

Working with video stills

Animation Idea with vector graphics

<videoflash type="vimeo">57355494|500|340</videoflash>

Collecting New Footage

Final Work

<videoflash type="vimeo">58303903|500|340</videoflash>

The video footages, taken by our DIY microscope appeared very roughly. The resolution as well as the image quality were defined by glitches and a certain limitation in color and saturation. At the same time the aesthetics were new to us and we were impressed by the visual outcome of accidents and random happenings. We started by focusing on aesthetical aspects and the idea to combine a micro and macro world. For that we were inspired by a video detail of one second from Alfred Hitchcocks movie "the birds" from 1963. Which is one of the first commercial movies that adapted experimental video and sound effects. After animating the footage with vector graphics we assembled the surfaces with microscopy videos that are matching to the objects. By changing the video elements with several visual and timing effects we aim to carry further an abstraction.