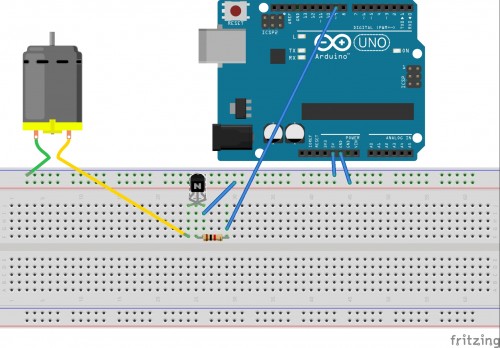

Schematic of One motor:

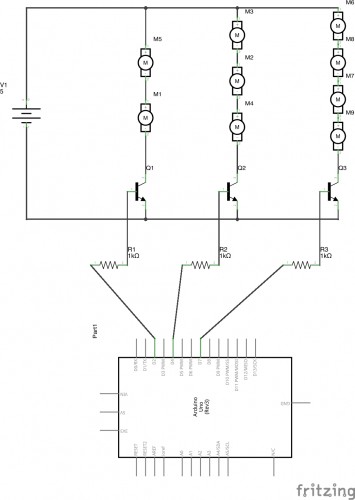

Design of Several Motors in Serial and Parallel Design:

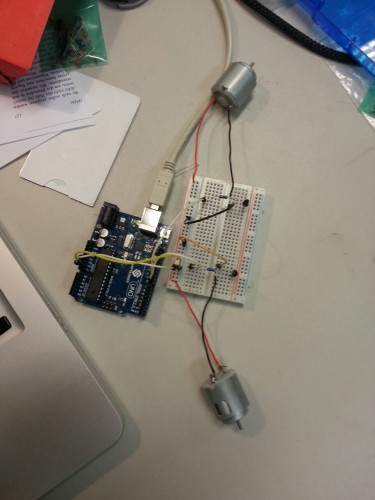

Test of parallel motor:

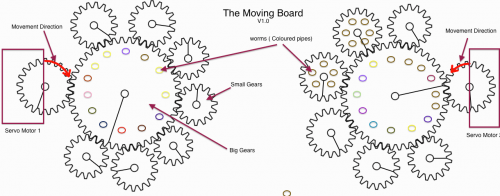

This is the first prototype of Moving Board V1.0.

Movement achieved:

1: Bi-directional circular, half-circular or any circular motion depends servo motor.

3: Worm Bi-directional rotation around fixed point.

Check out how it moves. (I don’t know for what ever reason the board can’t be loaded for simulation.)

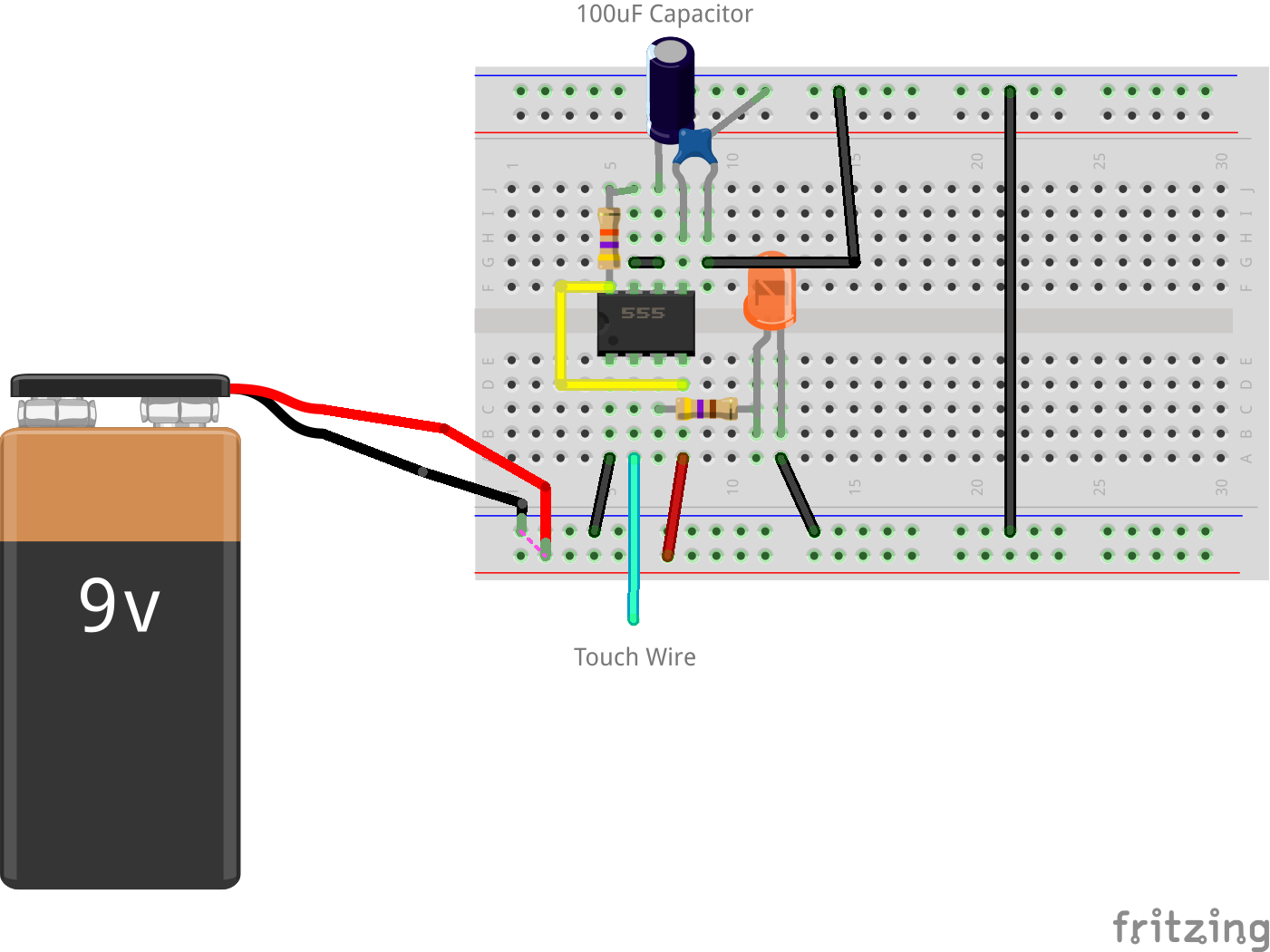

This is the touch sensor that will be used for our gun prop. It’s easy to build and works well. I also included the Fritzing file I made for it in case someone else wants to use it.

What you need:

A nice sensor for Object recognition in its surroundings, this detects a new object with in 20 feet far.

conductible yarn / glowing yarn / …

http://www.funfabric.com/halli.php?020500

this suit could be a good base for a diving-suit:

belts / fabrics / …

extremtextil:

Sketches:

Sketch for the Pipes:

Fogmachine: Scotty II

http://www.thomann.de/de/smoke_factory_scotty_ii_akku_fog_machine.htm

Pro´s

Con´s

“The smallest fog machine of the world!” (L = 9,8 cm, B = 4,4 cm, H = 3,4 cm), but is very expensiv (819,-€) and doesn’t produce enough smoke-pressure.

That is something from a modell airplane. It produces 1,5 minutes of constant smoke, uses 1600mAh batteries, 150mL of RedOil smoke liquid and is it a other option next to normal fog maschines, with a higher pressure.

http://www.smoke-el.de/home.html

That are very cheap Smoke Pellets, but they need to be set on fire.

Because they are get really hot, you need for example a large tin with another smaller one in it for the insulated. To distribute the smoke, a ventilator would be good.

For the pipe you can use tube from the building supplies store, but it must be heat-resistent and the tube should not sit directly on the fog mashine so that the machine gets air.

The smoke can flow well, when the tube has a diameter of 4 cm and more.