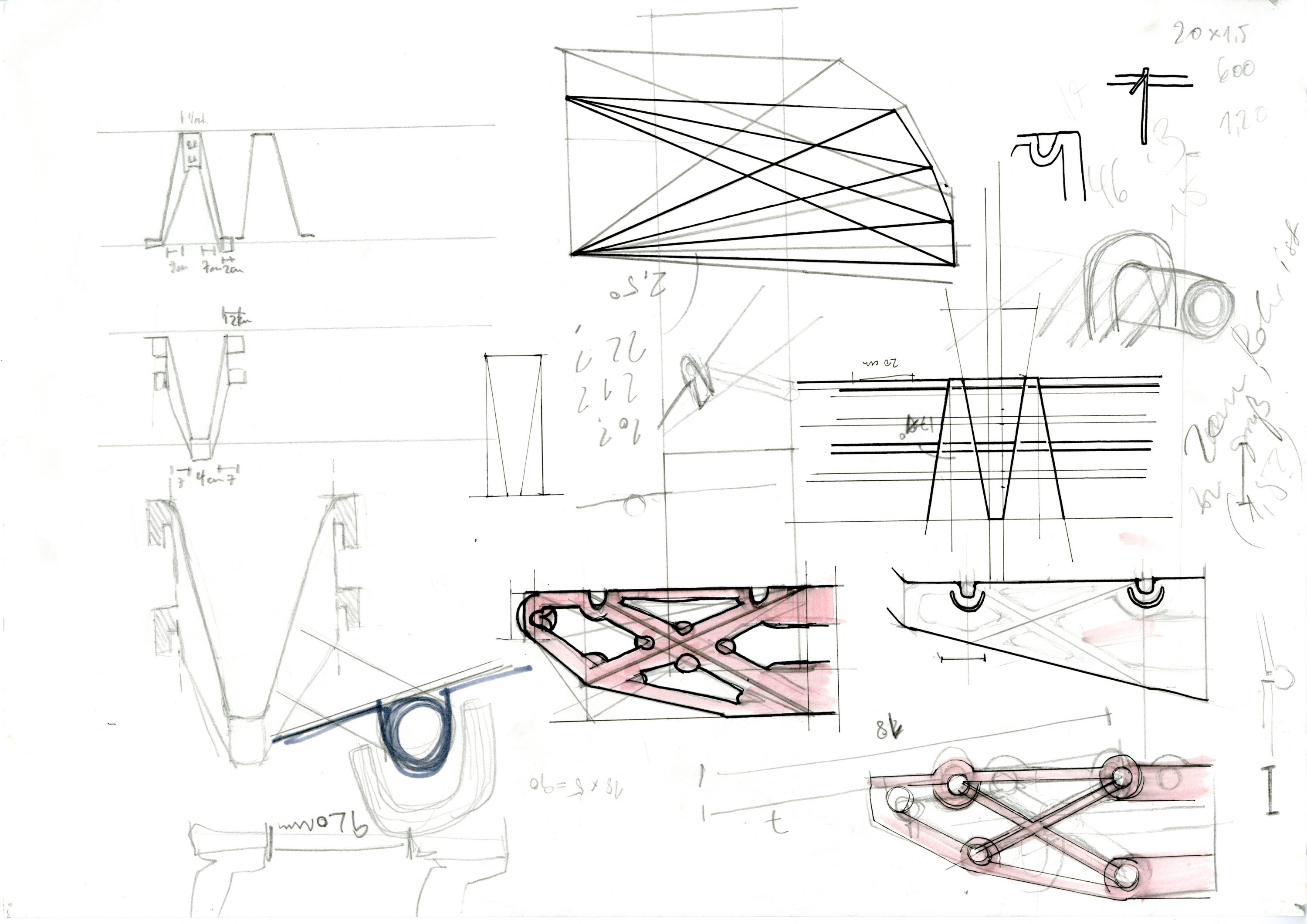

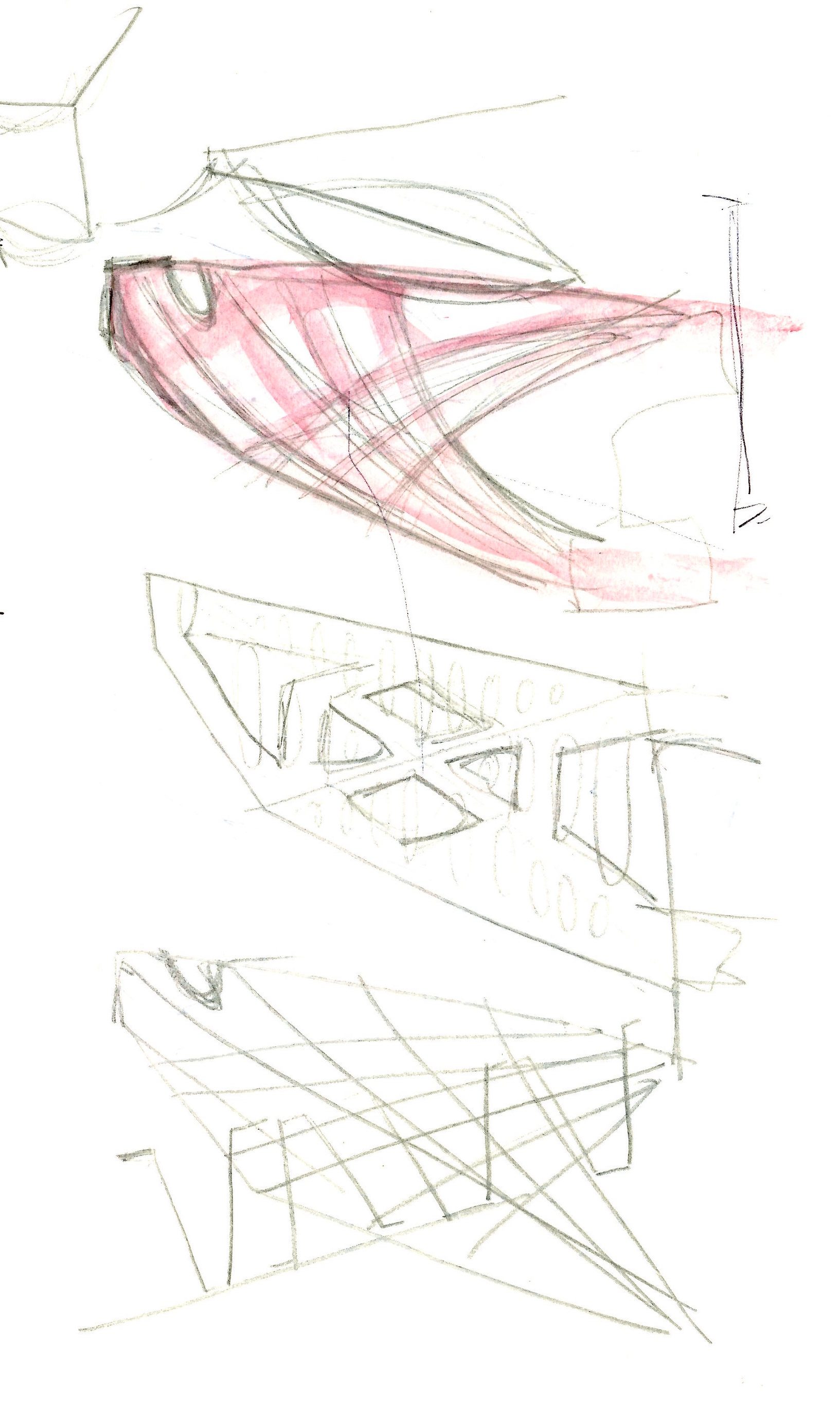

Finally, I worked out a scheme for the luggagrack that would allow individual repetition and simple assembly of the pieces. Via waterjet cutting and bending it is possible to achieve a lightweight sheetmaterial solution for the cantilever board-modules.

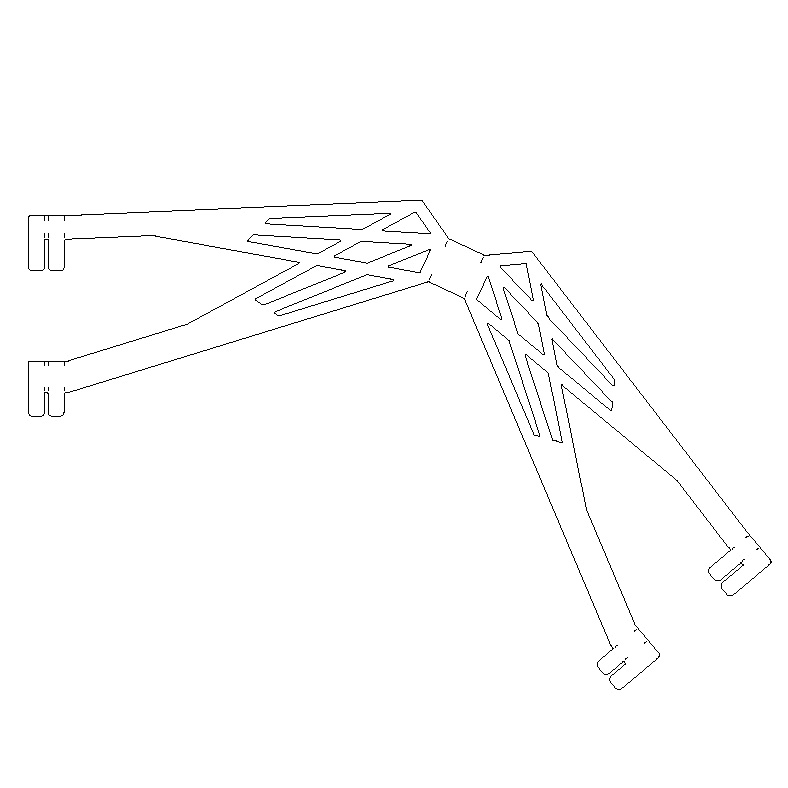

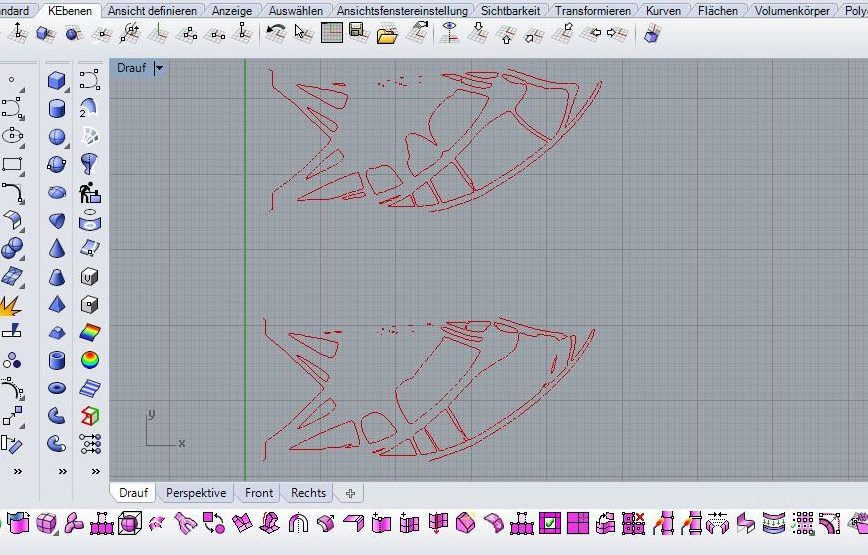

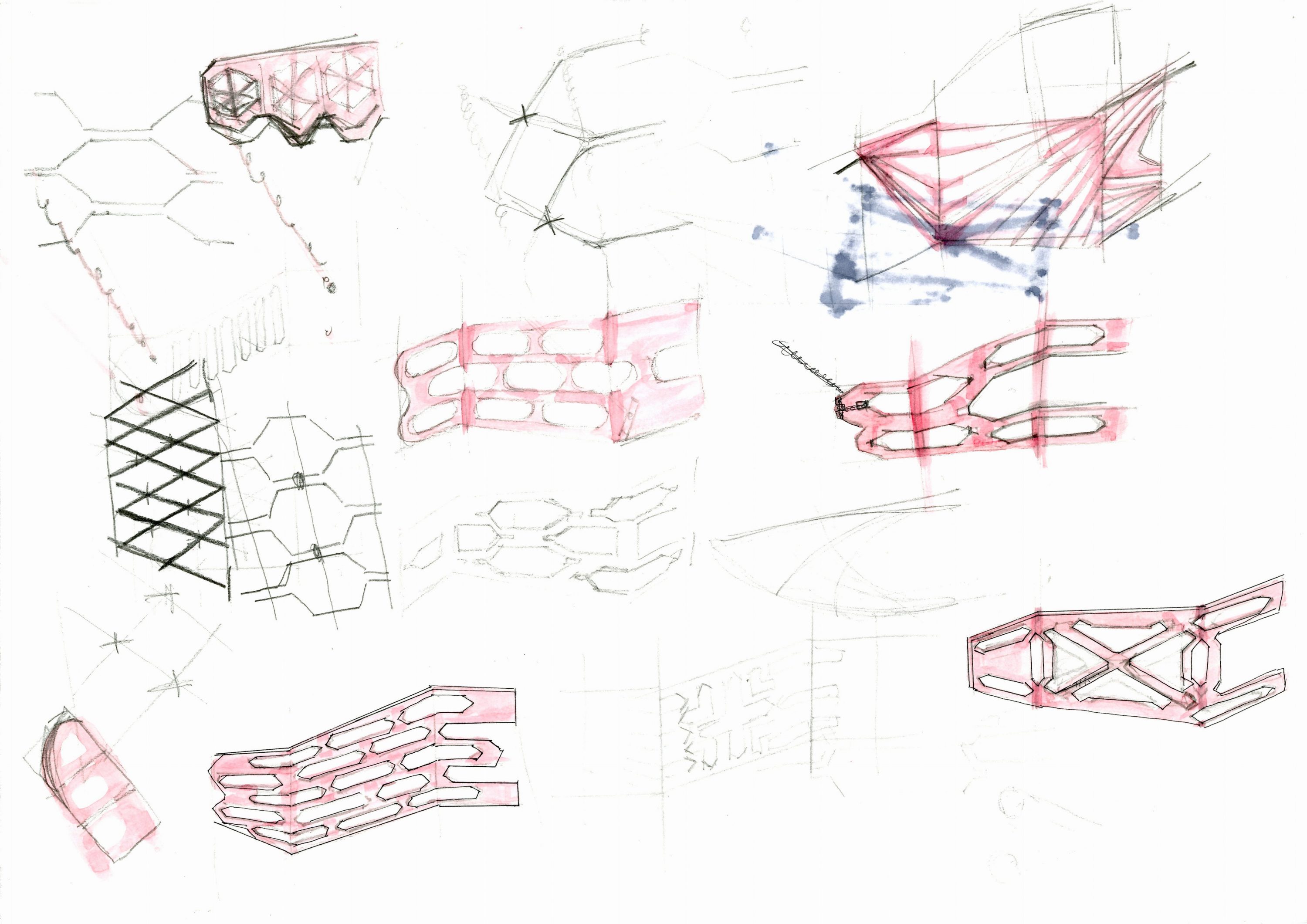

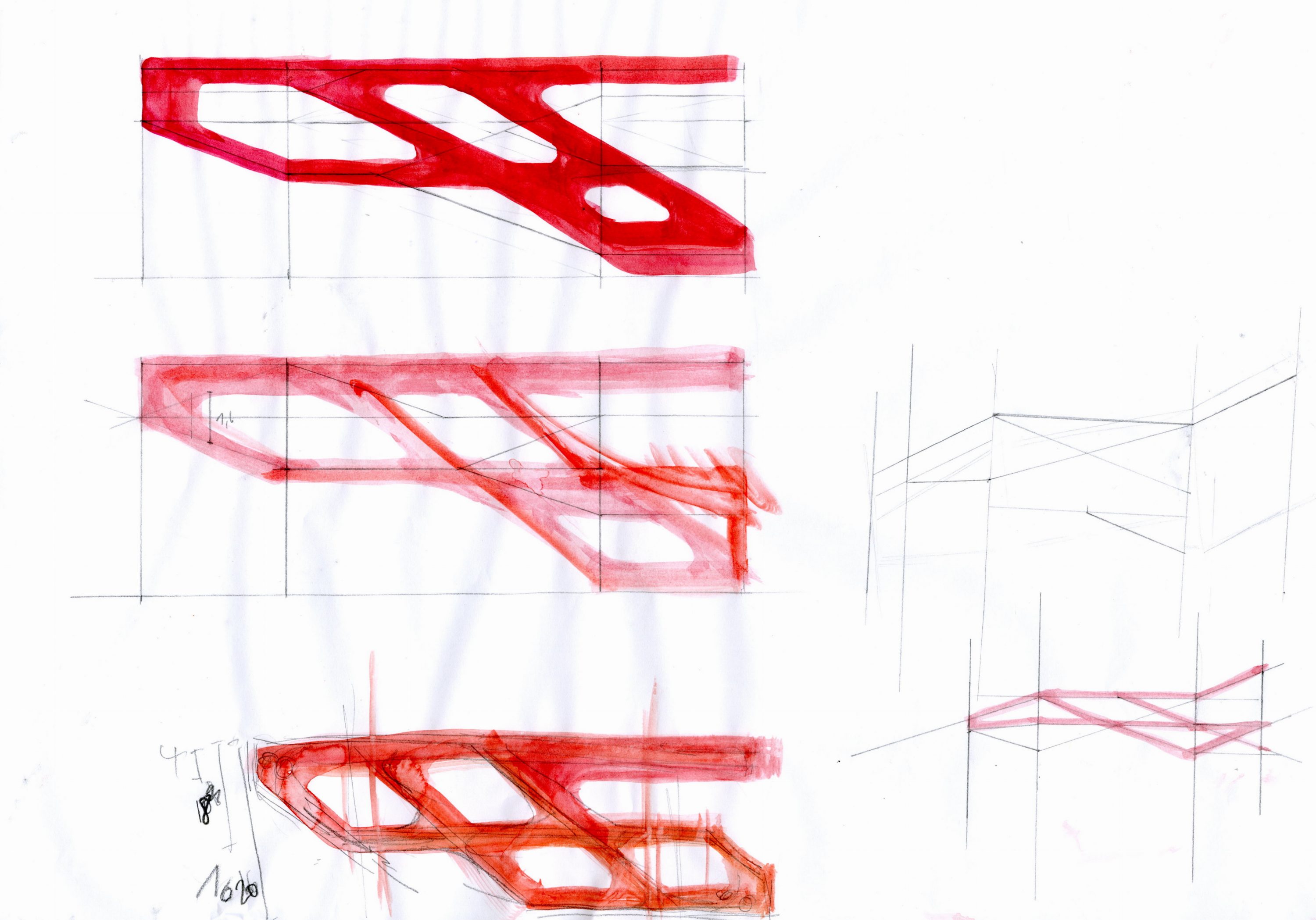

2D calculations of the cantilevers sideview showed a pattern, that i translated into a cutout pattern.

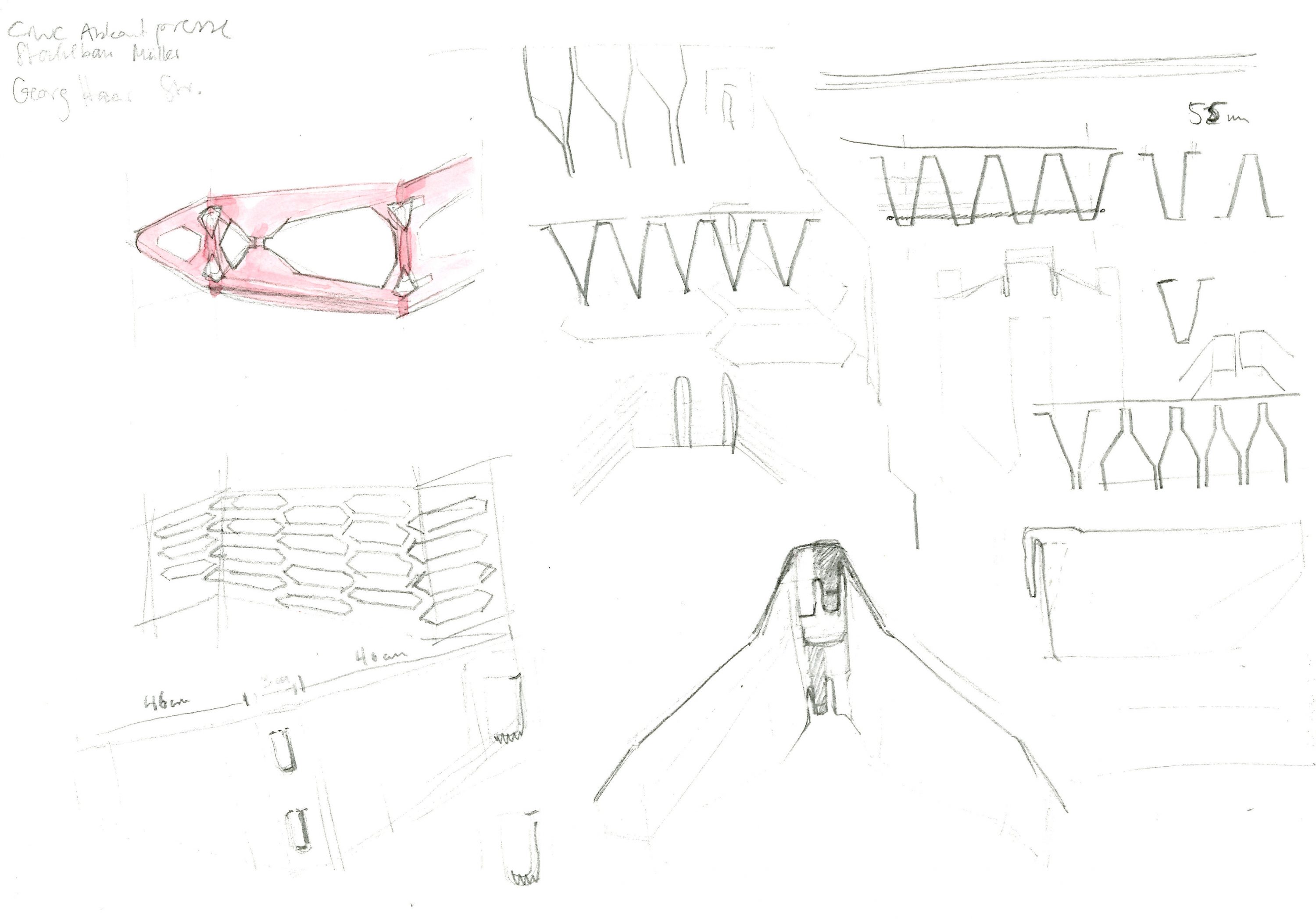

I felt the need to work out the pattern to a cleaner structure. The assemblypart sits on the backbent ends of the modules and clings into a profile on the wall. To diminish the complexity when it comes to mounting the pieces, two cantilevers are always connected at their front end and form one cutout piece.

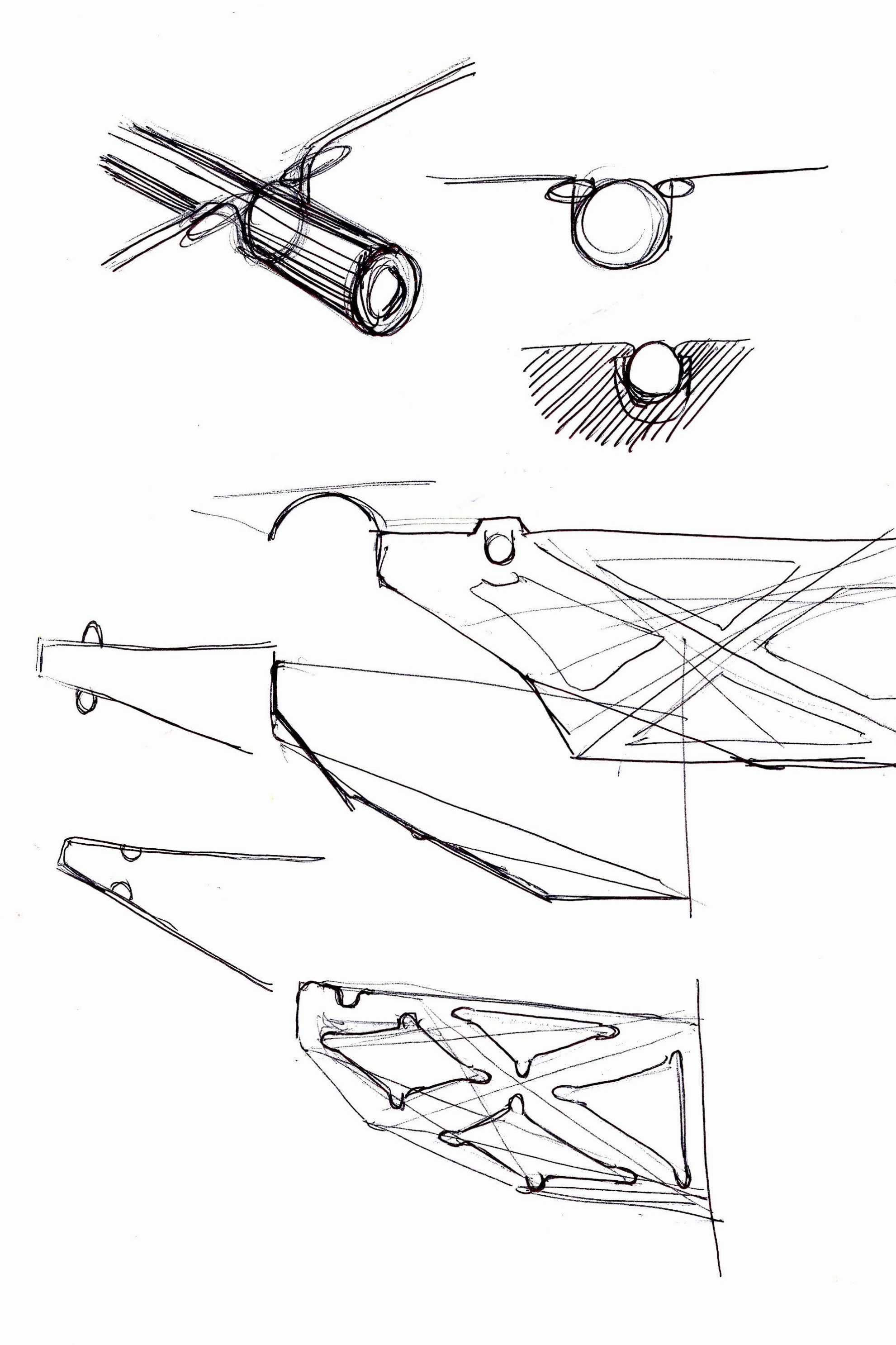

I have spent some time thinking about the connection of the single pieces on the frontside, for a visual effect of connection and stability, but especially as a rim when it comes to shifting the luggage on top of the rack.

In the end, small bent metalsheet pieces were added to achieve an alternating pattern in the front view, while still providing the needed rim with little material used.

the finished pattern as seen below was waterjet cut and bent in the workshop.