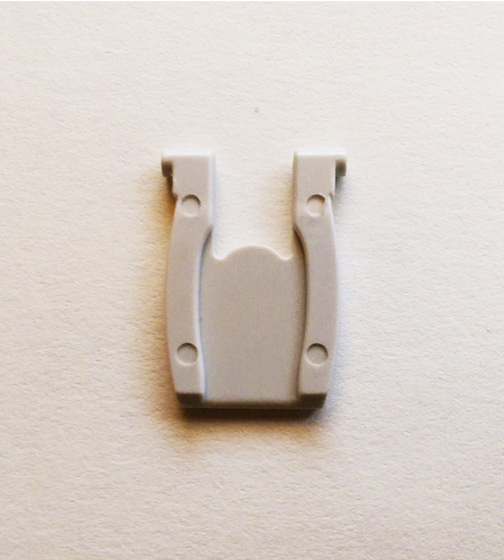

In my first small project, I work on keyboard feet as they break through again and again.

The aim is to produce a light foot which can withstand the stresses better.

Since the keyboard foot is relatively small (27mm x 19mm x 3mm), and the boundaries of the 3D printer through its extruder nozzle is 0.4 mm,

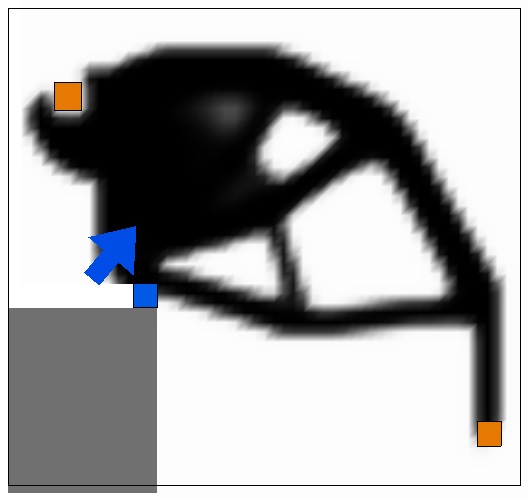

I can keep the resolution of the computations relatively low.

2D calculations yield only 2D images, which, however, represent more detailed results compared to the 3D results.

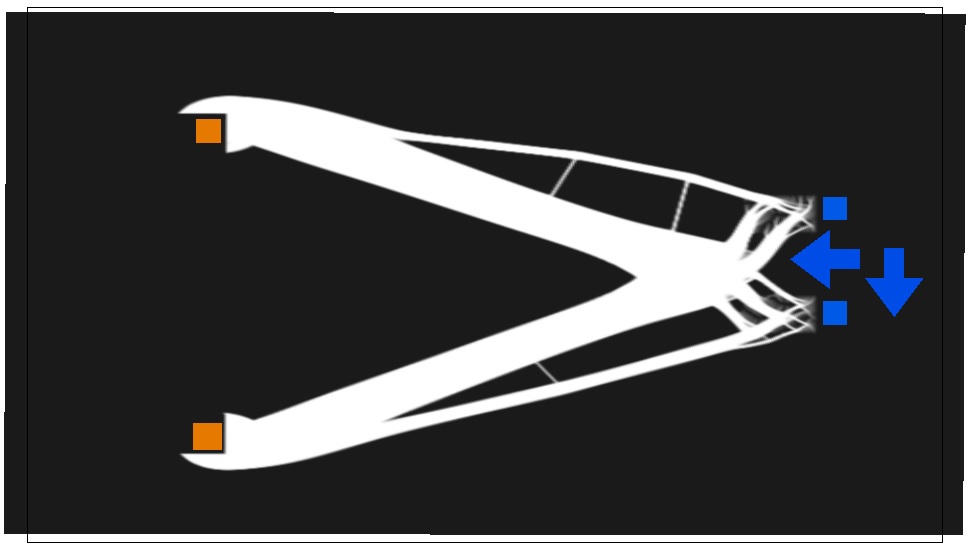

By interpreting the results, I have built a CAD model that should meet the requirements of the keyboard foot.

I put the two results on front and side view. With this basis I constructed the CAD-model.

I have 3D-printed the model. Where I have not made high-quality printing, since I want to see how much the foot does,

When a piece of 8 minutes of production time is required and weights 1.5 g.