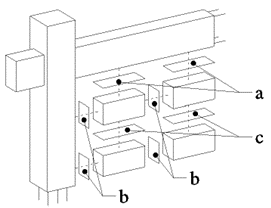

Converting a physical specimen into a finite element model typically involves several

steps.

First, the

specimen's geometry must be accurately measured and modelled in the software. If there

is

symmetry, one

can

exploit that by adding supports, as the stresses and strains are usually just mirrored

images. By doing

so,

the calculation time is significantly saved.

Next, the material properties of the materials used in the specimen must be determined

and

input into

the

software. This information can be obtained through testing and experiments or by using

values found in

the

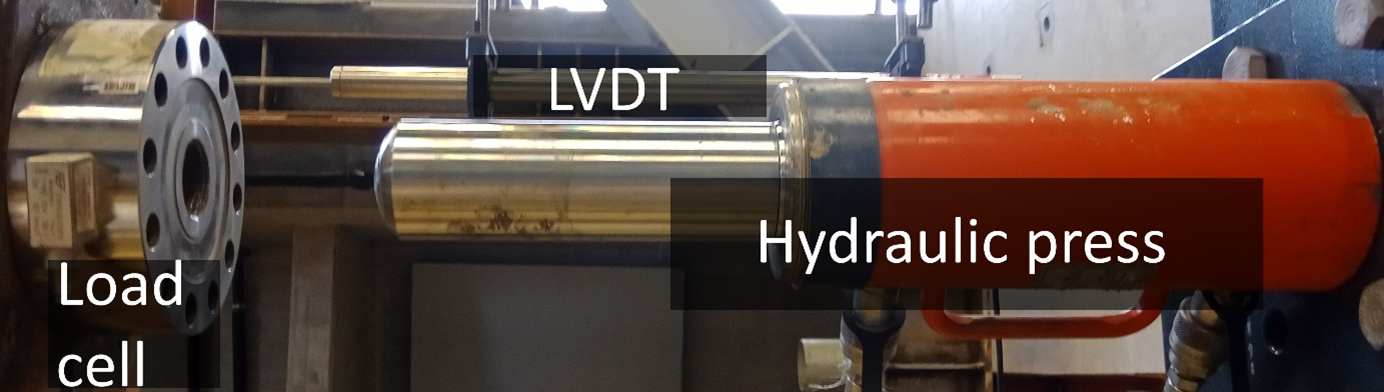

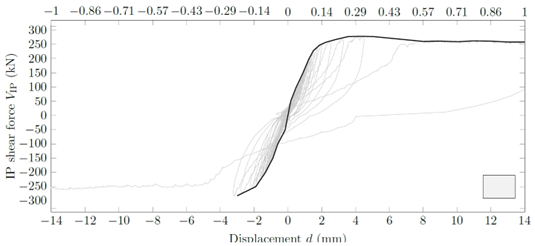

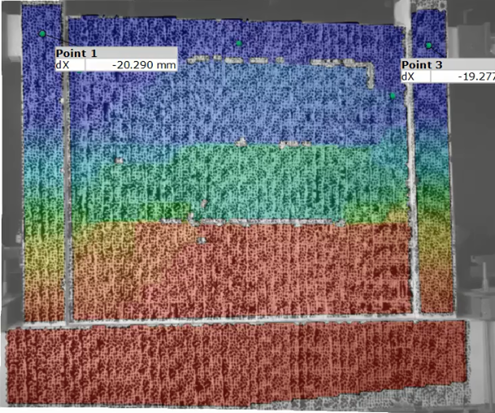

literature. In this example, we had tests of each material involved in the specimen and

that

of the

in-plane

test that you can see on this screen.

Once the geometry and material properties have been established, boundary conditions

must be

defined to

reflect the conditions of the physical specimen. This includes constraints, such as

fixed or

pinned

supports, and loads, such as gravity or externally applied forces.

Next, the finite element mesh must be created, dividing the specimen into smaller

elements

suitable for

numerical analysis. The mesh must be fine enough to capture important details in the

specimen, but

coarser

elements can also help speed up the calculation time.

Finally, the finite element analysis is performed using the software, in this case,

Atena,

using the

defined

geometry, material properties, boundary conditions, and mesh. The analysis results can

then

be compared

to

the results from physical testing to validate the model and refine the material

properties

as necessary.

In summary, creating a finite element model of a physical specimen requires

understanding

the specimen's

geometry, material properties, and loading conditions, as well as a detailed mesh and

proper

analysis

setup

within the software.